BUILDING AN 8-POINT ROLL CAGE

My chromed

roll bar is sold to Doug Youth in Hawaii, so the roll cage will not be an addition

to the roll bar.

It will be entirely built from scratch, pretty much like this sketch.

When we were in Atlanta for the SSHS-5 race in 2005 I looked around for B-bodies

with roll cages to see

how they had solved it. There were only a handful of cages to see. Here's the

solution in all-out racer

"Black Wolf" of Karl Ellwein where they just put the bought cage kit

further back inside car to avoid

the hassle of going through the instrument panel which would be a nightmare.

Just like my sketch,

and this is the way I'm going as well.

The main

loop dummy in progress. The design will differ a little from the roll bar loop

because

of the forward going bars. The cage will be made in chrome moly and the main

loop here will be

in 1 3/4" - rule book says 1 5/8" but as the SS is much heavier than

the normal race cars I

thought a little stronger would be a little better. The rest of the bars in

this cage will be

according to the rule book 1 5/8" - 1 3/8" and 1 1/4"

It will be

very tight for the head loop, especially since I want to keep the sun visors.

I finally thought that the head loop was too difficult to make, and it would

not look good, so I went on

to make longer front bars instead. It's fun to make dummies.

You can only come so far with cardboard. When bars need an angle you need something

else

to work with.

I called an electrician I know. Classic VP pipes in PVC is perfect. 40 mm is

a standard in Sweden.

Heated up quickly with propane and cools off slowly so that you have time to

hold it in the angle you want.

It ain't pretty but it works. The straight parts and the outer radius is the

important information for

the professional chassie builder who is going to do the bending of the chrome

moly tubes.

Once again Bengt Wittander of Competition Cars in Lund will do this for me.

The pipes give you a lot better visualization of looks and clearance. Parking

brake pedal, brake release,

hood opener, light controls etc. need to work as normal.

There will be two cross bars as well, under the panel in 1 3/8" and at

the top of window in 1 5/8".

Rear bars were easiest to make. Absolutely straight backwards and only two bends.

As in the case when I built the roll cage a couple of years ago, I managed to

save the speakers also

this time. Here the speakers are replaced with blocking lids, done by the drag

racing rules if you

have a fuel cell in the trunk.

Actually there was only one place, one way, to put this bar through the hat

rack if avoiding speakers,

and trunk lid hinges and stuff. I chose the point in the frame a little bit

rearwards so the bar won't

interfere with eventual bigger wheel tubs, if in a future I want to build that.

This is the way they did it in Snowflake with an Alston Chassieworks 6-point

cage. Not a streetcar as

you can see. All function, no glamour. Snowflake has gone 10.60 by builder Bernie

Steinke, an IHRA

Pro Stock mechanic. However, in Atlanta it was owned by Brian Herter but borrowed

and raced by

Glen "Stumpy" Koenig - and me! And it was very close I got to test

this cage...read about it.

A couple of days in The Best Damn Garage In Town and the work is done! Now Bengt

Wittander of

Competition Cars in Lund will take it from here and make reality of it. I really

look forward to seeing

it translated to chrome moly!!

Hm?

Wittander will also update

2005 Bilsport Pro Mod European Champion Patrick Wikström's

Tim McAmis 2000 Camaro. No cardboards, no plastic pipes...how can they communicate?

Stock SS carpet is much thicker and made of more plastic (back side) than the

one I bought from Street

Trends in Calsbad, California. New carpet is only 1/3rd the weight! And this

weight reduction means that

the Blackout SS will be lighter with new roll cage! Excuse me, but isn't that

called...luck?

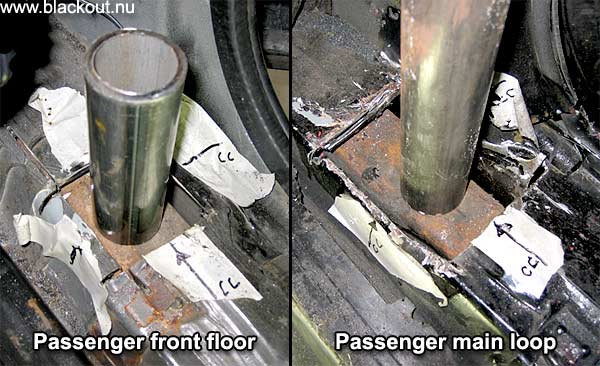

Floor has never been in the open before. Rusty surfaces but not too bad. Needs

a little brushing

and paint to make me feel good.

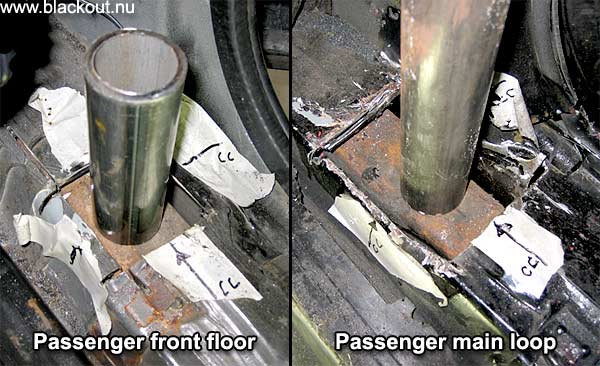

Some violence and cursing was needed to cut off the main loop bolt plates. They

were welded good to

the thick floor! Now they're soon off to the new roll bar owner in Hawaii, Doug

Youth!

Looking good!

When waiting for the bent bars from Wittander, I had time to fit the new carpet

to the car.

It's just wonderful to get the roll cage kit like this from Wittander! Every

end is a little extended so I'll

need to put these chrome moly pipes onto the dummies to begin cutting, a little

at the time.

So far - so damn good! First evening I managed to fit the main loop! It takes

time since you want a

perfect fit at the welding points (and the frame isn't that flat everywhere!)

But here it stands...

Looks like it's tailormade for the SS. =)

Just like the bent plastic dummy. I'm so happy!

This is just what I have been longing for to see.

Backseat passenger side. Must give enough clearance between bar and roof for

padding.

Looking good.

It's really tight clearance to get the rear bars straight in the car. I even

had to cut off the levers for the

trunk lid torsional bars to be able to lower and raise the frame when it's time

for welding.

Apparatus Roll Barus And Cagus Extremus Smartus - borrowed it from Jonas Alholt

who just has

released his new company: Weld Done. Or was it Very Weld?

What can I say 1?

What can I say 2?

The final dummy could be made now when the frontbars are in their positions.

This bar will also be

made out of 1 5/8" chrome moly.

Bengt, this will be toughest one of them all. Three bends, three different angles.

That's because the

front bars are different.

What can I say 3? That jig I borrowed from Jonas Alholt must have saved me a

week!?

So, the final bar bent by Wittander - the window cross bar - is fitted to the

rest of the cage and now

all bars are ready to be TIG-welded together, first tack-points then we lower

the chassie for full

access to weld full 360 degrees on all joints.

Missing here would be the crossbar in the main loop (safety belt rear anchor)

and the lower crossbar

just above the legs. The latter one will come on last of all. Here I've taped

up the passenger side

side bar in its position to see how it's going to be.

The (absolutely too heavy) Alston Chassis Works' swing outs will be placed so

when sprint is removed

the side bar will drop to the floor (on a rubber stop something) giving space

for in and out movement.

Same design on driver's side.

The rear swing out placing.

Nice to get going again! First a round of Scotch-Brite to get a better contact

for the weld. Then Jonas

Alholt tack-welded it with the TIG.

Everything is important to a perfectionist. Jonas didn't allow me to tack-weld

with the MIG.

"I'll do it with the TIG instead, it will be better!" Next: drop the

frame...next week.

Well, after having been convinced by Mr Alholt I've decided to skip the elephant-weight-swing-outs

and

am now building permanent side bars like this. Yes, I know and I'm sorry to

all you SS-fans but I then

have to cut some material out off the door side as you know! But it's "only

an inch or so". I promise

you to do it carefully and as nice as possible so you all get to know what can

be done! Forgive!

This is the big advantage in doing it permanent. You'll get an 8-point cage

instead of a 6-point.

Let's see some wonder TIG over this now! Jonas where are you?

I'm glad I'm so athletic...he hm. And I really wonder what will happen at the

yearly inspection for the

Swedish Traffic street legal certificate...? I hope it will be a young inspector

taking on the SS...an

athletic girl or so? And sorry for the mess! But everything's under control!

If Kajsa can - I can...

Sorry for the mess 2. How about that cross bar? I know Mr Alholt will love it...he's

over me big time!

Safety belt retaining loops on the inside (aiming towards back of the seats)

of the cross bar. Jonas is

using the welding helmet and gloves he gave me on my recent birthday. Bit by

bit we're creating an

Impala SS roll cage Extra Ordinary. Bragging? Absolutely!

Tacked in place, the long diagonal bar and the rear cross bar. Missing here

is the diagonal cross bar

from the main loop (behind driver's head) over to the rear bar to the left in

picture, which we will place

there when the cage is lowered.

It goes to this lower point. Two cuts in the floor will make it possible to

lower the frame from the body so

we get better clearance for the full TIG weld. Next step is actually to lower

the frame! Yahoo!

Many many hours in these 11 small 3/4" chrome moly tubes. Many.

Frame on its way down and the cut channels work just fine.

Meanwhile some action from my wife Agneta, who brushed the rust surface out

of the car.

And painted it with zink ground afterwards. Dear Agneta - kiss hugs kiss!

It will be lowered even more before welding. The rubber body bushings will be

changed to

polyrethane ones when frame is going up again.

I just love to see these TIG-welds!

And I thought that I was athletic...Jonas is ready for the Olympics...

All eighteen 1 5/8" joints are done! Next time we'll take the eleven small

3/4" ones.

Meanwhile I'm preparing the boxing of the factory weak u-frame on both sides,

at the main loop points

at least. I wonder how many SS-owners in the world who have done this? Driver's

side boxing.

Passenger's side.

To find the right grey color for the roll cage was interesting, since Chevrolet

didn't bother to have

the same tone of grey all over the interior. I guess there are 3 or 4 different

tones of grey in there!?

Not even the seats are complete, can you see that the head restraint is more

blueish!?

In choosing I did go for the "most represented" Chevrolet grey in

the interior. That is a warmer

more yellow (not so blue) tone. I've also noted that a perfect match like above

looks

a little bit off on a flash picture like this. Hm?

You see, different greys all over. Front panel, front panel top, Inner roof,

B-pillar plastic, door padding,

door handles....I guess I have chosen something in the middle?

Frame down to a maximum with engine, trans and rear end still there. It's lowered

a little more

than 30 cm/1 foot. Brake lines'n'stuff are kind of straightened out =)

All to get Jonas happy with the clearance. Here he's working on the driver's

front point. But he still is

grumpy because he likes RACE CARS which have total access and hates STREET CARS

because

of the lack of access. I have heard that before, from "Baker" Bergqvist

among others...

But HEY guys, it's fun when it's done!

Darth Vader working on the small ones. Just love welding pictures without flash.

Darth Vader again. Click picture to see a full size version...

The rear point on passenger side.

Suddenly all was welded!

And even Jonas was satisfied (kind of) after an inspection. Thank you for a

Weld Done job!

So a couple of hours later I could put on the primary ground paint. Not too

easy I might add.

Happy afterwards!

The paint job has to be done in at least two stages, when the frame goes back

up again.

FAMILY CAGED IN THEIR CAR!

Grinding, spraying, grinding, spraying... Hot! No air! Chemicals! Nowhere to

escape!

Ahhh!!! How wonderful it is to have had come this far! The paint is on! Cheers!

Rear points painted black, as the rest of the trunk.

"Boxy but good"

It feels very good to have this U-frame boxed with some 3 mm steel plate.

The padding went on. Next the frame will go up into the SS again. The project

has come to its turning

point. Cheers!

The frame went back up again and Jonas could reach to do the last TIG-weld of

the front cross bar.

This is down at the driver's side.

The Acrobat Welder! Thank you Jonas!

There it is!

The work to cover the holes in the body started directly. This is driver's side.

There is some

remaining paint job since some parts of the tubing were of course hidden in

the body before.

Passenger side. All welding now done, thanks to a very speedy professional.

Now some body filler to this and finalizing with zink primer by the brush.

Agneta working hard to freshen up everything in the interior. The car has never

been so fresh before!

Now when relying more on the strength of the frame and roll cage, the body sills

holes are just covered

with aluminium and silicone. Next: the interior back in! This is the driver's

side Main loop.

This is the Driver's side front. This also shows that I have some painting to

do.

This is the passenger side Main loop.

This is passenger side front.

Wonderful!

Wonderful!

Terrible action with a lot of measuring before cutting in to the underneath

of the textile cover of the

hat rack. You just do this once! But it turned out to be just wonderful!

Wonderful!

Wonderful! But hey Doug, I need those speaker covers real soon now! Don't send

to Autoshop,

send to me directly!

Wonderful!

Terrific! I will modify the soft armrest padding later.

Amazing!

Terrific!

Consol going back in. I modified it to hide a lot of cables that irritated me

before. I also made a small

hole to be able to have the EGT cable (exhaust gas temperature) coming straight

up to the EGT-

instrument. This cable was just on the passenger side floor before.

At last I could bring back driver's front seat and mount the safety belts in

the cross bar.

Good side clearance! Mmm, it feels so new and fresh!

Who do you think was the first to sit again in the car?? "Move away"

Jonas told me and entered in a

rarely seen jump. He liked it. And I think part of it is because he just came

from a completely different

world in drag racing - lightweight and as lightweight as possible! That was

the story with his Melmac

Mustang with twin turbo 289 which he just sold! Now he deals with this 2 ton

- 4444 lb HEAVYWEIGHT!

I think he likes the contrast! But I've seen him begin to throw away washers

from my Blackout SS!!

The big Sit-In has begun! Melle and Mona wanted to test out the new roll cage

interior.

As did Mr Top Fuel Thore. Everybody likes the caged interior and was also surrpised

by the SS comfort.

And at last the glove compartment lid is back in place after a couple of years

on the shelf. All the

electrical wiring will disappear when FAST-boxes are connected.

It's very tight between lid and roll cage, 1,5 mm, as expected. I was holding

the tube right there when

Jonas welded it to the frame.

Some sharkbites to begin with! I'm working on the tube clearance in the door

side pads.

The Big Sit-In continues every day...

A friend from our childhood in Umeå - Nisse Malmhäll visited relatives

in Gothenburg and wanted to

visit me and our SS in

my garage as well. Nisse works at the "scary" Svensk Bilprovning (second

picture

on this page) as a technical expert. I had him to pass my Impala SS on the

spot. Then he got coffee.

Agneta cleaned the last areas of the interior. What a difference it has made!

Thanks Agneta!

"Dad?" Yes what is it? "Can I start?" No you can't just

yet... "Uhh, it's so unfair!"

Nice with the new mats with deer logo.

You can clearly see the difference in the grey tones in the interior in a flash

picture like this.

I'm glad it's much better in real life.

The back seat, where you can sit and drink beer and shout...

The dome light cover had to be cut even more this time to make it fit together

with the main loop. Yep.

Rolf "Loffy" Lundberg, Linköping, Technical Grand Master of Swedish

Drag Racing - a chapter within the

Swedish Automobile Sport Federation (FIA-sanctioned) - visited TBDGIT on his

"spring tour" of 2007

going through several racing garages in south of Sweden and Denmark. He came

by to inspect Patrick's

updated Pro Mod Camaro and my roll cage and eventually pass them? Gulp...

"Loffy" checks all dimensions and thicknesses of the cage.

"Loffy" finally sticks the "award" to the cage. Good to

go 7.50 with the Blackout SS!

Final picture.